Wiring terminations are faster and consume less space when made using multi-level terminal blocks.

Terminal blocks are the fundamental product used to interface wires and cables to internal components for any type of electronic or electrical equipment. Designers need reliable and easy-to-use products arranged to make the best use of the limited space available. Classic screw-type single-level terminal blocks are the typical method, but these are relatively inefficient. Responding to customer needs, Wonkehas developed higher-performing, multi-level, spring-type options to provide the best performance in small spaces, especially for multi-conductor cable applications.

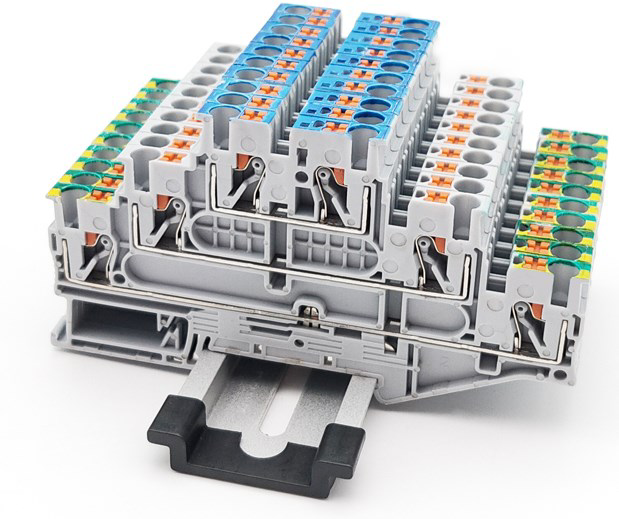

Figure1 Wonke offers combined of terminal blocks and accessories, including multi-level designs, to help designers cost effectively save space, simplify installation, and make troubleshooting more convenient.

Beyond Basic Connectivity

Basic 'feed through' terminal blocks have one wire connection point on each side, with a conductive bar between them. This electrical portion resides inside an insulated housing. Some terminal blocks mount directly to back panels, while other styles install on DIN rails or may be stacked side-by-side to save space. Designers must select terminal blocks with the right voltage, ampacity and physical sizes to match the application.

Standard terminal blocks can be bulky and consume valuable panel space. The classic screw-type connections often have screws and washers that can be lost, or they may require ring or fork lugs to be crimped on to wire ends. Screwing down each terminal connection point requires tools and takes a tremendous amount of time. Once assembled, the screws must be correctly torqued to ensure a proper connection. Too loose will cause the wire to overheat or disconnect, while too tight can result in a stripped screw or snapped screw head. Some designs use a spring cage-type connection, which is a screwless design that can accept a bare wire, or a wire with a pin ferrule crimped on to the end. However, this style still requires a tool for both wire insertion and wire release, which is still not optimal, taking up time and requiring the proper tools to accomplish.

Wonke offers JUK Series screw-type terminal blocks and JST Series spring cage type terminal blocks, because some users and industries have specific technical, commercial, or historical reasons for continuing to use these traditional products. However, each of the potential issues with screw-type and spring cage type terminal blocks can be overcome by using newer JPT Series multi-level push-in design terminal blocks offered by Wonke.

Figure 2 Wonke’s JPT family of terminal blocks incorporates push-in spring-type connectors with single-, two- and three-layer form factors in a variety of sizes.

More Connections, Less Space

Many power and control circuits, ranging from 24VDC up to 240VAC, consist of two-wire circuits. Signaling applications are often two-wire or three-wire circuits. To address these use cases, a natural choice is to incorporate multiple levels within a terminal block so that all conductors of a two- or three-conductor cable can be terminated in one clearly identified area (Figure 3). Furthermore, many signal cables also have a shield conductor, so Wonke also offers the JPT2.5-PE-L-N, a multi-level terminal block which includes an additional connection point to ground the shield to potential-earth via the DIN rail.

Figure 3 Multi-level JPT2.5-PE-L-N, terminal blocks, like the Wonke family of products, provide a compact and reliable way to make industrial-grade wiring connections.

Some users are concerned that multi-level terminal blocks can be harder to work with because of the density. However, Wonke has developed multi-level terminal blocks with users in mind, so the physical dimensions and marking provisions make them easy to use. For example, the DP2.5-3L is a typical three-level terminal block accepting 2.5mm2 size wires, where the overall width may be only 5.1mm, yet six conductors can be terminated, saving 66% of the valuable control panel space as compared with using multiple PT2.5 single-level terminal blocks. Even the JPTTB2.5, a two-level terminal block, can save up to 50% of valuable space compared to the single level terminal blocks. Multi-level terminal blocks speed up installation and make it easier for personnel to troubleshoot any issues because all of the related terminations are close together.

Scan and follow WeChat